Orbital Welding System

AutonoWeld Orbital Welding systems deliver closed-style TIG precision for high-purity tube and pipe welding, combining repeatable quality, field-ready durability, and intelligent power control.

Closed-Style Precision

Built for the Field

Intelligent Stystem

Orbital Welding Components

From micro-diameter tube welding to heavy-wall pipe fabrication, AutonoWeld Orbital components are built to perform in demanding environments where weld quality and production efficiency cannot slip.

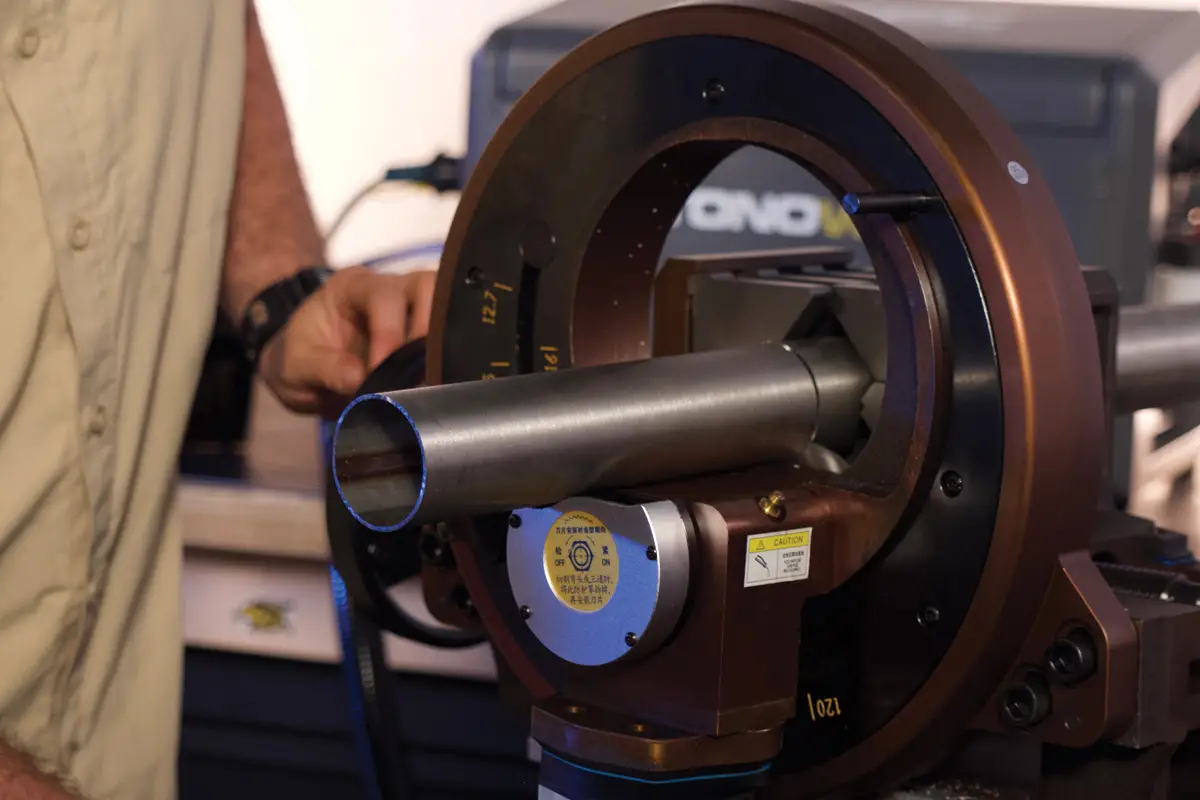

Macro Weld Heads

Built for heavy-duty fabrication, the AutonoWeld Macro Weld Head Series is designed for thick-wall pipe and mid-to-large diameter tubing. These closed-style fusion heads deliver full 360° orbital TIG weld capability with water-cooled reliability for consistent performance in both shop and field environments.

The Macro lineup ranges from compact to heavy-duty configurations, allowing fabricators to match output capacity to production demand without sacrificing precision or control.

Micro Weld Heads

The AutonoWeld Micro Weld Head Series is engineered for high-purity, small-diameter tube welding where access is limited and tolerances are tight. These heads bring full closed-style orbital precision into cleanroom, pharmaceutical, semiconductor, and instrumentation environments.

Both micro heads share a sealed, water-cooled design and balanced construction for all-day production without overheating or drift.

Power Supply

The AutonoWeld AW-215 is the control center behind the entire orbital welding system. Designed to deliver smooth, stable TIG current across a wide range of materials and wall thicknesses, it pairs instantly with all S-Series weld heads and automatically detects head type for fast setup and reliable operation.

The AW-215 combines rugged physical construction with intelligent digital control, delivering repeatable weld quality, real-time data visibility, and production-grade traceability.

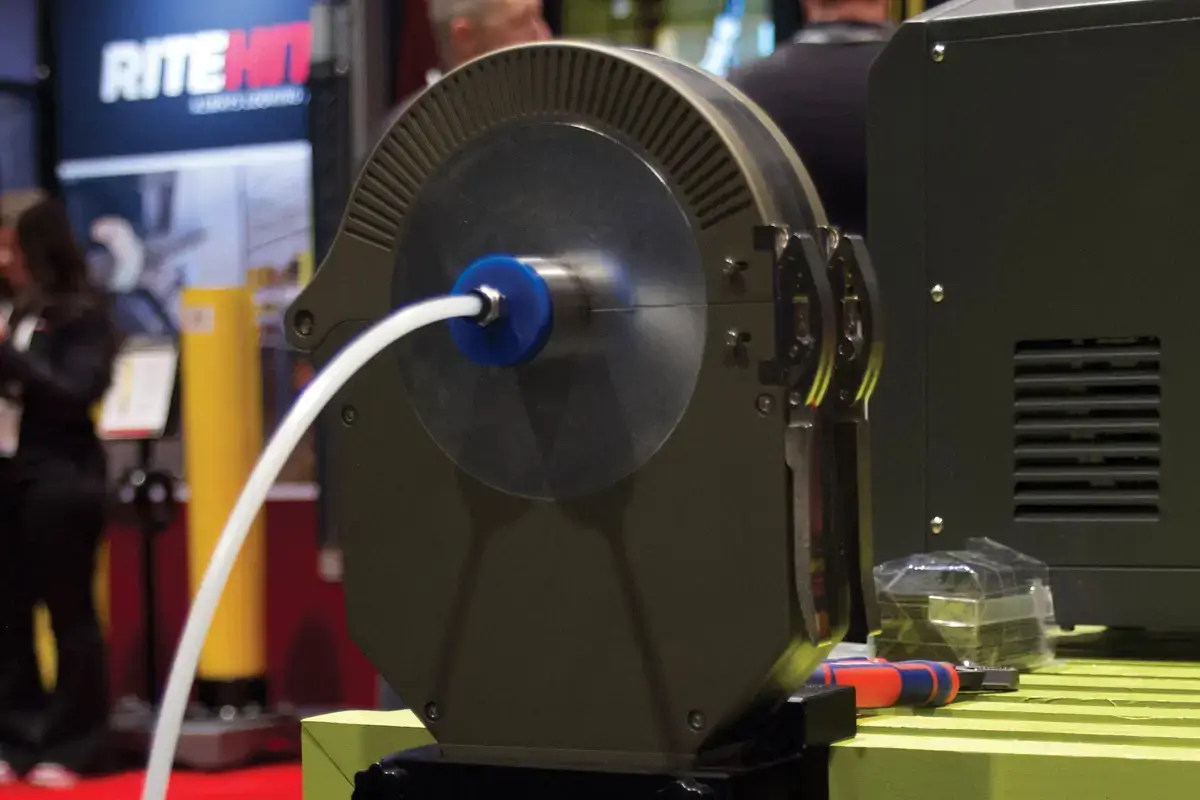

Tube Facing Tool

The AutonoWeld Tube Facing Tool ensures perfectly square, burr-free tube ends for precision orbital welding. Designed to deliver consistent edge preparation in both shop and field environments, this tool helps eliminate misalignment, reduces fit-up errors, and improves final weld quality across stainless, carbon, and alloy tubing.

- Facing Diameter Range: 0.125 in to 4.50 in depending on model

- Max Wall Thickness: Up to 0.393 in on larger models

- Power Output: 305 W to 1,020 W depending on configuration

- Rotational Speed: 300–400 RPM for fast, consistent edge prep

- Key Features: Cold cutting, automatic centering, burr-free finish, planetary cutting design

Orbital Cutting Saw

- Cutting Range: Supports tube and pipe from 0.25 in to 4.50 in depending on model

- Max Wall Thickness: Up to 0.276 in depending on material and diameter

- Rotational Speed: Adjustable 30–160 RPM for controlled, precision cuts

- Supported Materials: Stainless, carbon steel, aluminum, copper, plastics, titanium

- Key Features: Concentric clamping, cold cutting design, interchangeable blades, burr-free finish