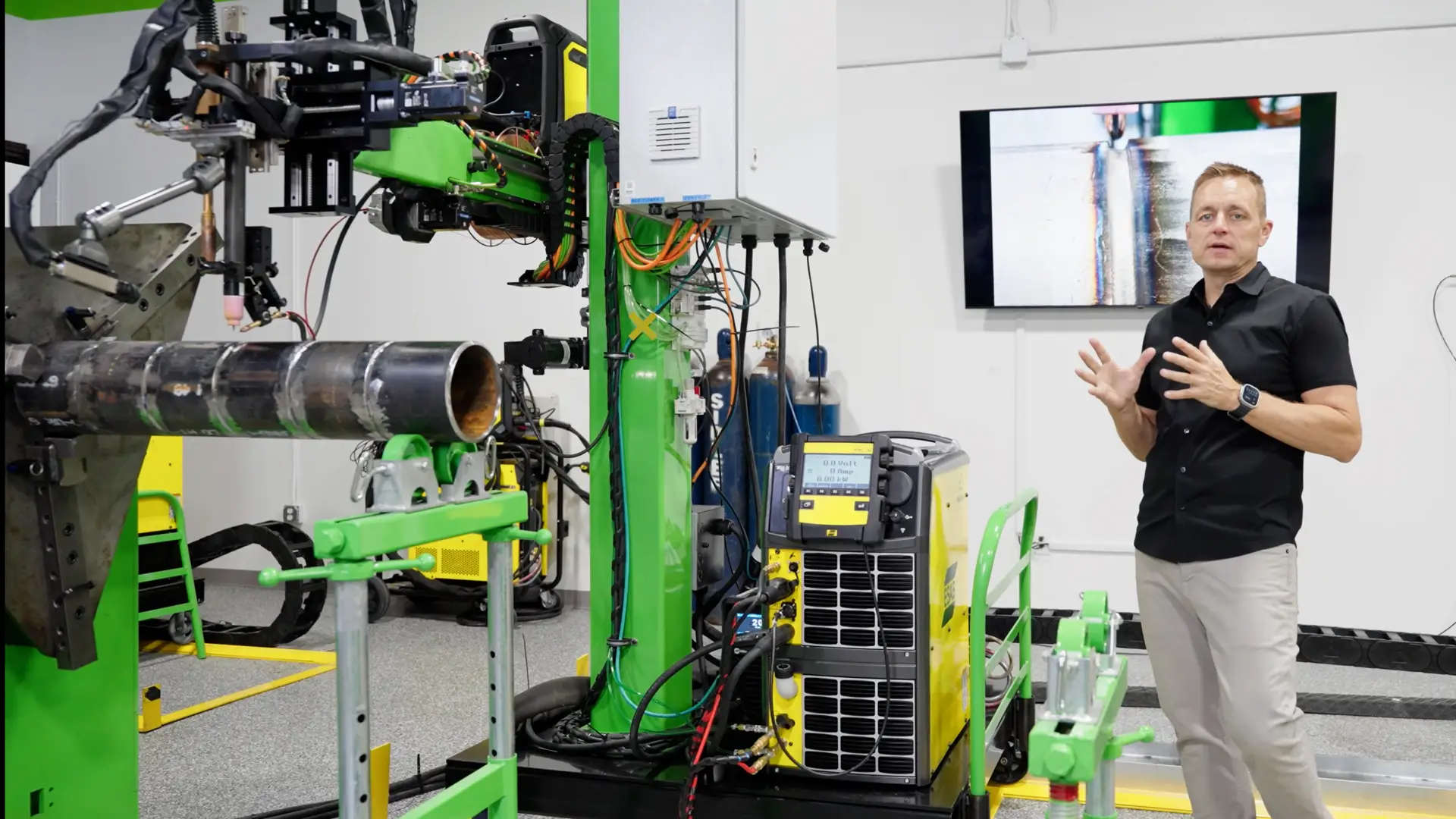

Pipe Spool Welding System

AutonoWeld Pipe Spool Welding Systems are designed to streamline spool assembly, deliver consistent weld quality, reduced fit-up time, and scale output for industrial fabrication workflows.

Precision Control

Fully automated TIG parameters deliver consistent, repeatable weld quality for spool fabrication.

Fabrication Ready

Durable, continuous-duty design built for shop environments and high-volume production cycles.

Smart Automation

Programmable weld schedules, automated positioning, and real-time monitoring.

Introducing the AutonoWeld M3 Pipe Spool Welding Machine

AutonoWeld M3 is more than a machine—it’s designed with the demands of pipe fabrication in mind. Custom-engineered and field-tested, these spool welding systems are intended to support repeatable weld quality across a wide range of applications.

AutonoWeld M3 Overview

The AutonoWeld M3 is a fully automated, multi-pass welding system engineered for precision spool welding at scale. Built for performance and repeatability, it’s ideal for high-spec applications that demand tight tolerances and minimal rework.

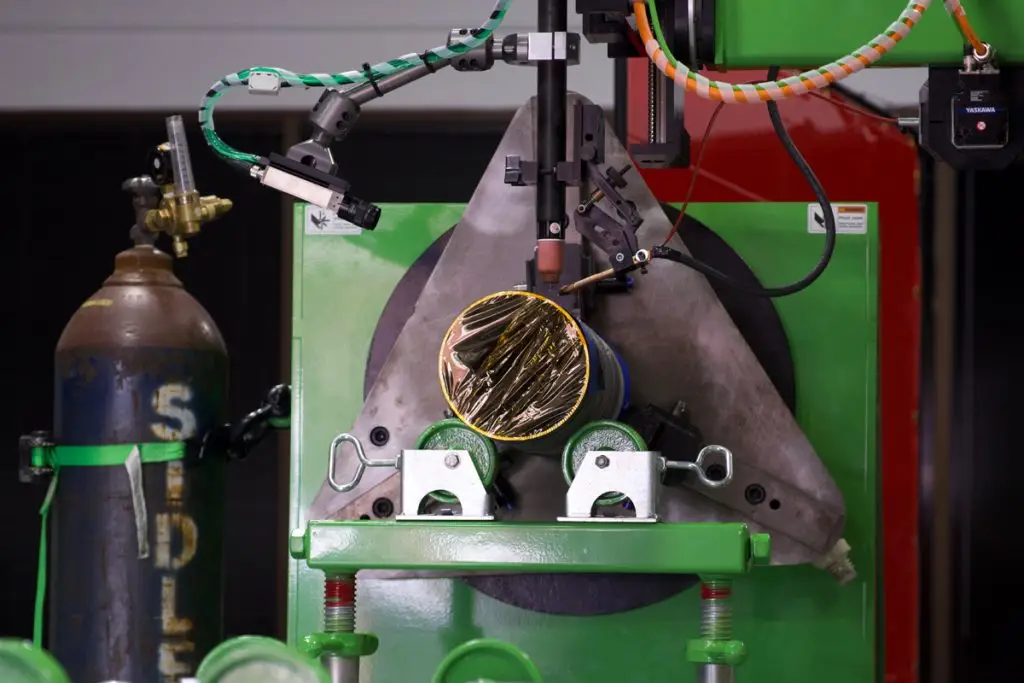

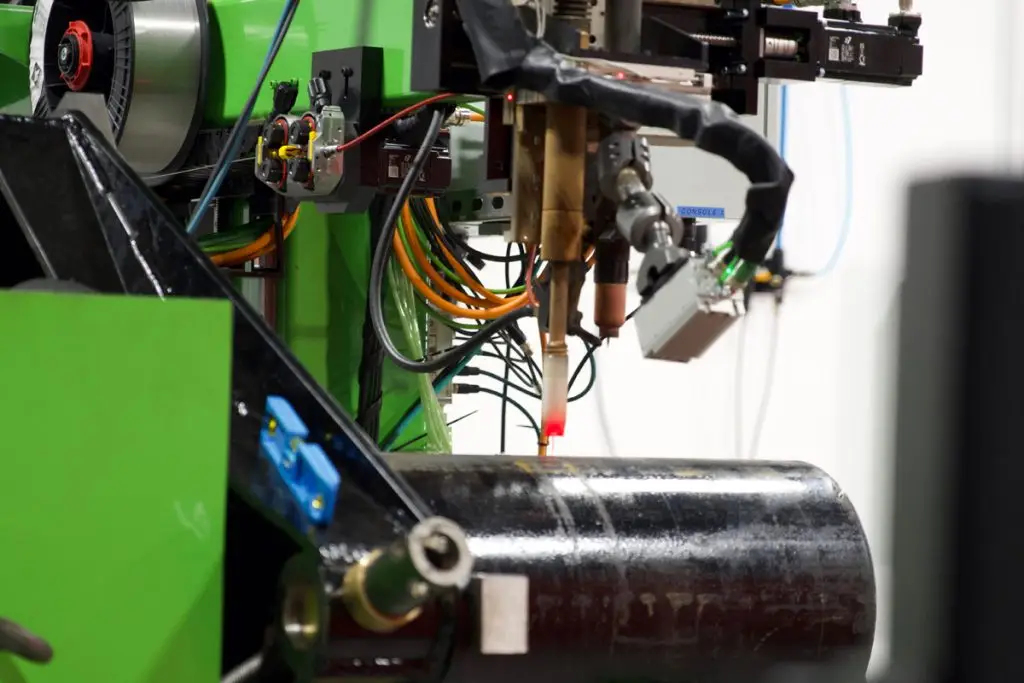

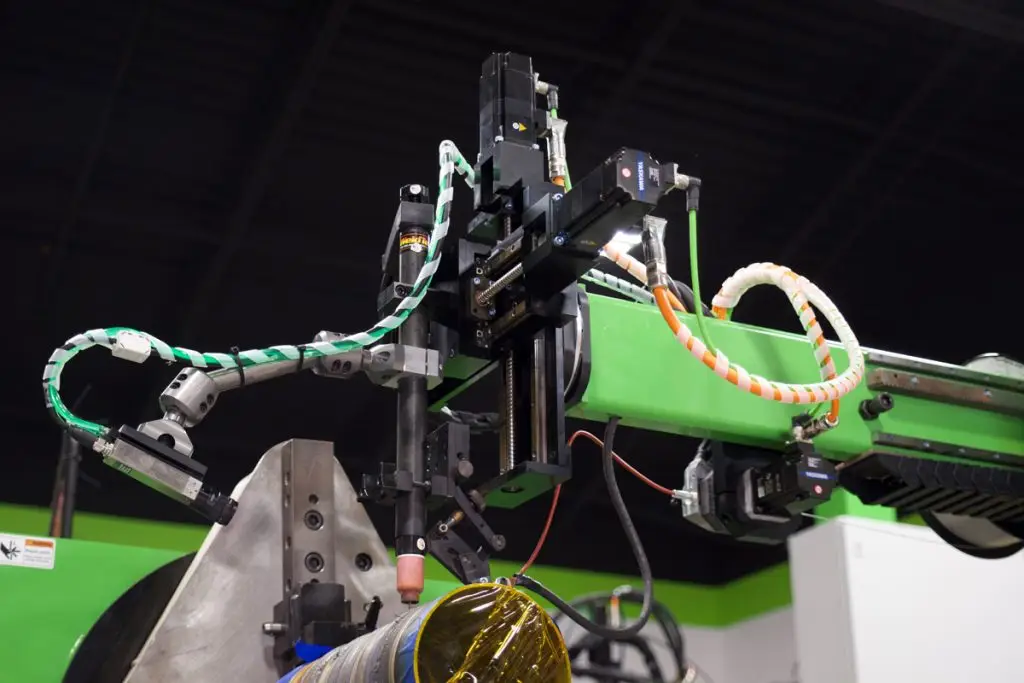

This system features integrated hotwire TIG, a programmable PLC touchscreen, and intelligent vision monitoring, all working together to deliver clean, consistent welds with low heat input and exceptional arc-on time.

Key Features

- ESAB Aristo 5000i Welding Package - precise setup and power source convenience in any job setting

- Cavitar Weld Vision System - specialized real-time weld monitoring, detection, and performance tracking

- AutonoWeld Hotwire System - unique technology to enhance overall weld speed, quality, and efficiency

- Training/Installation - Engineered for straightforward installation and intuitive operation, reducing training time and operator learning curves

Specifications

- 3000 lb and 6000 lb. positioners with pipe gripper

- Height-elevating manipulator with cross slides with 12” stroke

- PLC controlled with 15” touchscreen

- 25' 45' & 65' welding cell length options

- 2-36" diameter capacity

Video Walkthrough